Understanding Flat Roofing Felt Types for Your Property

Look, after twenty-three years installing and repairing flat roofs across Queens, I've worked with every type of roofing felt you can imagine. And here's the thing - most property owners have no clue what's actually protecting their building from our notorious New York weather. So let me break down the flat roofing felt types that actually matter for your property.

Built-Up Roofing (BUR) Felt Systems

This is the granddaddy of flat roofing systems. I've installed probably 800+ BUR systems in Queens alone, and when done right, these things last decades. The system uses multiple layers of roofing felt - usually three to five plies - with hot asphalt or cold adhesive between each layer.

The felt itself comes in different weights: 15-pound, 30-pound, and even 43-pound options. Most of our commercial jobs in Long Island City use the heavier felts because of the wind exposure from the East River. Last month we did a warehouse on 43rd Avenue, and the wind was so brutal during installation that anything lighter would've been a nightmare to work with.

Here's what you need to know about BUR felt types:

- Organic felts - Made from recycled paper and rags, saturated with asphalt

- Fiberglass felts - More dimensionally stable, won't rot or absorb moisture like organic

- Polyester felts - Premium option, incredible tensile strength

I'll be honest - organic felts are pretty much obsolete now except for historic restorations. We did the roof on a 1920s building in Astoria last year where the landmarks commission required organic felt to match the original construction. What a pain that was.

Modified Bitumen Systems

Now this is where things get interesting. Different types and varieties of flat roof felt in modified bitumen systems give you way more options than traditional BUR. The base sheet - that's your foundation layer - typically uses a heavy polyester or fiberglass reinforcement.

APP (Atactic Polypropylene) modified systems use a plastic-modified asphalt that gets torch-applied. SBS (Styrene-Butadiene-Styrene) systems use a rubber-modified asphalt that stays flexible even in cold weather. Given our Queens winters, I usually push clients toward SBS systems.

The cap sheet is where you really see variety. Granulated surfaces, smooth surfaces, foil-faced - each has its place. For a building in Flushing where the owner was worried about energy costs, we installed a white granulated SBS cap sheet that reflects probably 80% of the summer heat.

Single-Ply Membrane Considerations

Technically, EPDM and TPO aren't "felt" systems, but I get asked about them constantly when discussing flat roofing felt types. These synthetic rubber and thermoplastic membranes have largely replaced traditional felt systems for new construction.

But here's the thing - when you're doing repairs or dealing with existing felt systems, you need to understand what's already up there. I can't tell you how many times I've gotten calls where someone tried to patch EPDM over an old BUR system without proper preparation. Water gets trapped, and you've got a mess that costs three times as much to fix properly.

Choosing the Right Felt System for Queens Weather

Our climate here is brutal on roofing materials. We get everything - hurricane-force winds off the water, ice dams in winter, and those summer heat waves that make the roof surface hot enough to fry an egg. The felt system you choose needs to handle all of it.

For most residential buildings in Queens, I recommend SBS modified systems with a polyester base sheet. The flexibility handles our freeze-thaw cycles better than APP systems, and polyester reinforcement won't degrade like organic materials.

Commercial buildings are different. High-traffic roofs with HVAC equipment need something tougher. We just finished a school in Elmhurst where we used a three-ply BUR system with fiberglass felts and a mineral-surfaced cap sheet. Heavy-duty, but it'll handle the foot traffic from maintenance crews.

Installation Quality Matters More Than Material Type

Here's something most contractors won't tell you - the best flat roofing felt types in the world won't save you from poor installation. I've seen $50,000 modified bitumen systems fail in two years because the contractor didn't properly seal the seams or flash the penetrations.

When we install any felt system, every seam gets a minimum 4-inch overlap. Penetrations get base flashing, counter flashing, and often a third layer of protection depending on what's coming through the roof. It takes longer, costs a bit more upfront, but saves thousands in repairs later.

Temperature matters too. You can't install modified bitumen when it's below 45 degrees - the adhesives won't bond properly. I've seen contractors try to rush jobs in cold weather, and the results are always disappointing. We schedule around weather because doing it right the first time is always cheaper than fixing it later.

The substrate preparation is just as critical. Old felt needs complete removal most of the time, not just a patch-and-overlay approach. We stripped a roof in Jackson Heights last spring that had four different felt systems layered on top of each other. The deck was so compromised we had to replace sections of it.

Cost Considerations for Different Felt Types

Let's talk numbers because that's what everyone wants to know. Basic three-ply BUR with fiberglass felts runs about $4-7 per square foot installed, depending on the complexity of the roof. Modified bitumen systems typically cost $6-10 per square foot.

Premium polyester-reinforced modified systems can hit $12-15 per square foot, but they're worth it for the right application. We installed one on a medical building in Forest Hills where downtime for roof leaks would cost them thousands in lost revenue. The owner didn't blink at the premium price.

Don't forget about tear-off costs if you're replacing an existing system. That can add $2-4 per square foot depending on how many layers need removal and disposal fees. The city's pretty strict about proper disposal of old roofing materials.

Oh, and another thing about costs - get multiple quotes, but don't just pick the cheapest. I've been called to fix so many "bargain" roof jobs that ended up costing twice what a proper installation would have cost initially.

Maintenance Requirements by Felt Type

Different felt systems need different maintenance approaches. BUR systems with gravel surfacing need annual inspections to make sure the ballast hasn't shifted and exposed the membrane. Smooth-surfaced systems need regular cleaning to prevent ponding water issues.

Modified bitumen systems are generally more maintenance-friendly. The seams are heat-welded, so there are fewer potential failure points than mechanically fastened systems. But they still need annual inspections, especially around penetrations and drainage areas.

We set up maintenance contracts for most of our commercial clients. Spring and fall inspections, immediate repairs for small issues, and detailed reporting so they can budget for major replacements. It's like regular oil changes for your car - small investments that prevent expensive failures.

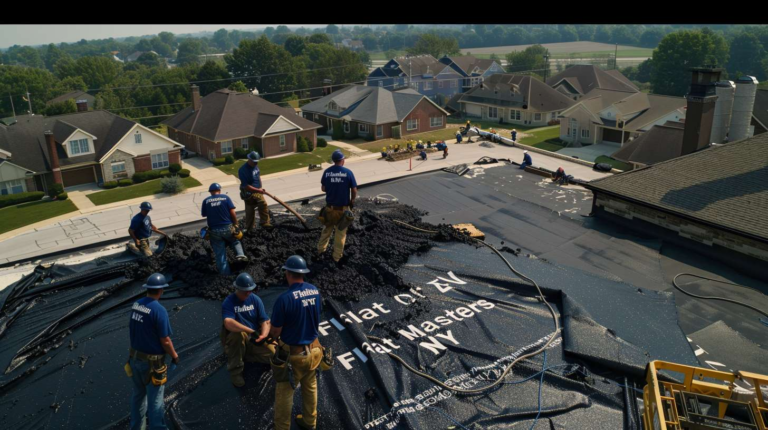

For property owners in Queens dealing with flat roof decisions, understanding your options for roofing felt systems makes the difference between a roof that lasts decades and one that becomes a constant headache. At Flat Masters NY, we've seen every type of installation succeed and fail, and we use that experience to match the right system to your specific building and budget requirements.