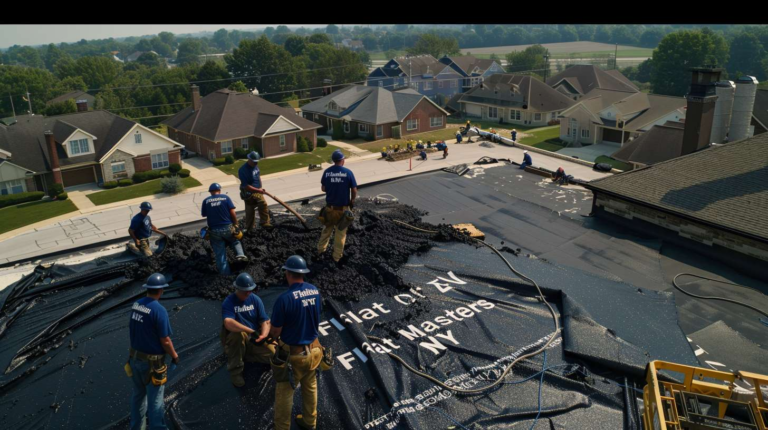

Professional Specialized Flat Roof Details & Expert Solutions

After twenty-three years working flat roofs across Queens, I can tell you that specialized flat roof details make or break a project. Most contractors skip the critical connection points - that's where your problems start. When I see a job specification calling for unique and specialized details, I know we're dealing with either a seasoned architect who understands flat roofing or someone who's learned the hard way.

Critical Ridge Tile to Flat Roof Detail Connections

The ridge tile to flat roof detail is where I see more failures than anywhere else. You've got two completely different roofing systems meeting, and if you don't handle that transition properly, water finds its way in every single time.

Here's what actually works: We install a custom fabricated metal transition piece that extends at least 8 inches onto the flat surface and ties into the ridge tile system with a continuous cleat. The membrane gets fully adhered up and over this transition, then we install a secondary flashing cap. I don't care what the drawings show - if there's not proper overlap and redundant waterproofing at this connection, you're going to have problems.

Last month on Astoria Boulevard, we fixed a ridge-to-flat connection that had been "repaired" three times by other contractors. The original detail had zero consideration for thermal movement. Every winter, the materials contracted and opened gaps. Every summer, they expanded and buckled. We redesigned the entire connection with expansion joints and proper flashing sequences.

Flat Green Roof Detail Complexities

Green roof installations require completely different thinking. The flat green roof detail isn't just about waterproofing - you're dealing with root barriers, drainage layers, growing medium, and plant selection. Most importantly, you need access to the membrane for maintenance without disturbing the entire ecosystem above.

We use a modified bitumen base with a specialized root barrier membrane. The protection board goes down first, then your primary waterproofing, then the root barrier. But here's what separates professional installations: the drainage layer design. Too many contractors just throw down some gravel and call it drainage. Wrong. You need engineered drainage with proper slopes, overflow drains, and inspection ports.

The weight calculations alone require structural engineering. A saturated extensive green roof adds roughly 35-80 pounds per square foot. Intensive systems? You're looking at 150+ pounds per square foot. That's a car parked on every 64 square feet of your roof.

Flat Dormer Roof Detail Solutions

Flat dormer roof details give contractors nightmares because you're creating a low point that wants to collect water. The key is understanding that this isn't really a "flat" roof - it needs positive drainage even if it looks flat from the street.

We always install tapered insulation to create minimum 1/4 inch per foot slope toward the drains. The dormer sidewalls get flashed with a two-part system: base flashing integrated with the membrane, then removable counterflashing that can be maintained without tearing up the roof. The front wall connection is critical - we use a custom fabricated drip edge that extends minimum 2 inches beyond the face of the building.

Flat Roof Balcony Details That Actually Work

Balcony connections to flat roofs are problematic because you're penetrating the roof membrane for structural supports while trying to maintain waterproofing. The flat roof balcony details we use involve creating a curbed opening with proper flashing integration.

The structural attachment points get isolated from the membrane system using penetration boots designed for the specific load requirements. We never just poke holes and seal around them - that's amateur hour. Each attachment gets a flanged boot that integrates with the membrane layers, then gets mechanically secured to the deck structure.

Drainage around balconies requires careful consideration. Water can't be allowed to pond against the connection points. We install secondary overflow systems and often add heating cables in areas prone to ice dam formation.

TPO Roofing Details and Installation Specifications

Flat roof TPO roofing details require understanding the material properties and limitations. TPO is great for large, uncomplicated areas, but the details require precise execution. The membrane welding at connections is where problems develop.

All penetrations get reinforced with additional membrane patches. The base flashing extends minimum 8 inches onto the horizontal surface, and we always use termination bars at vertical terminations. The membrane thickness matters too - we specify minimum 60-mil for most commercial applications, 45-mil only for simple residential installations with minimal foot traffic.

Temperature during installation affects everything. TPO becomes difficult to weld properly below 40 degrees Fahrenheit. Above 90 degrees, the material becomes too soft and can stretch during installation, creating problems later when temperatures normalize.

Flat Roof to Tiled Roof Detail Transitions

When flat roof systems meet traditional tiled roofing, the flat roof to tiled roof detail becomes a complex waterproofing challenge. You're dealing with different slope requirements, different materials, and different thermal expansion rates.

The transition typically requires a custom fabricated metal flashing system that accommodates the tile profile while providing proper overlap onto the flat surface. We extend the flat roof membrane up the vertical surface minimum 8 inches, install base flashing that integrates with the tile underlayment system, then add counterflashing that follows the tile profile.

The critical element most contractors miss is the secondary water barrier. If water gets past the primary flashing system, there needs to be a backup that directs water back onto the flat roof surface rather than into the building structure.

Hybrid Flat Roof Detail Engineering

Modern buildings often incorporate hybrid flat roof detail systems that combine different technologies for specific performance requirements. We might use modified bitumen in high-traffic areas, single-ply membrane for cost efficiency, and spray foam for complex geometries - all on the same project.

The connections between different systems require careful engineering. Material compatibility testing is essential. Some adhesives that work perfectly with EPDM will attack TPO. Some modified bitumen installations are incompatible with certain spray foam formulations.

We maintain detailed specifications for hybrid installations that include transition strips, compatible adhesives, and proper overlap requirements for each material combination. The details get complex quickly, but the performance benefits make it worthwhile for the right applications.

CAD Drawings and Technical Documentation

Professional flat roof details dwg files are essential for complex installations. We maintain a library of proven details that can be customized for specific project requirements. These aren't generic details downloaded from manufacturer websites - they're engineered solutions based on real-world performance.

The drawings include material specifications, installation sequences, and quality control checkpoints. Each detail shows primary waterproofing, secondary protection, structural attachments, and maintenance access requirements. We also include thermal movement calculations and expected service life for each component.

When architects provide flat roof details dwg files with their specifications, we review them against local building codes and our performance standards. Many generic details don't account for Queens weather patterns, local wind loads, or freeze-thaw cycles. We modify as necessary and document all changes for the permanent project record.

Quality Control and Installation Standards

Specialized details require enhanced quality control procedures. Each connection point gets photographed before and after completion. We maintain installation checklists specific to each detail type, and our crew chiefs are trained to recognize when field conditions don't match the engineering assumptions.

Weather monitoring is critical during detail installation. Wind speeds above 25 mph affect membrane handling. Temperature variations during installation can affect material performance for years afterward. We reschedule rather than compromise installation quality.

Every project gets a comprehensive detail inspection before final acceptance. We use electronic leak detection on all membrane details, thermal imaging to verify insulation continuity, and water testing on all drainage connections. The goal is identifying potential problems before they become actual problems.

At Flat Masters NY, we've learned that successful flat roofing isn't about using the cheapest materials or fastest installation methods. It's about understanding how different systems interact, planning for long-term performance, and executing details with precision. The specialized connections often represent less than 10% of the total roof area but account for 90% of potential problems.

If you're dealing with complex flat roof details in Queens, don't trust them to contractors who treat every job the same way. Call us at (917) 994-7618 for an evaluation of your specific requirements. We'll review the architectural details, assess site conditions, and provide recommendations based on proven performance rather than lowest bid pricing.