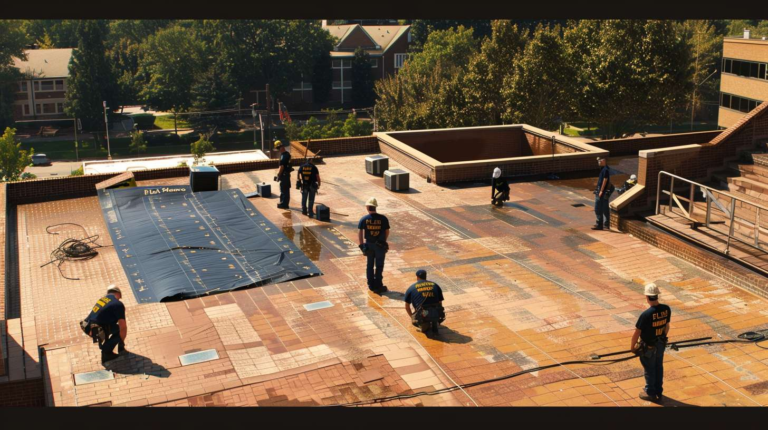

Best Flat Roofing Materials for Your Commercial Property

After twenty-three years installing flat roofs across Queens, I can tell you that choosing the right flat roofing materials for your commercial building isn't just about price - it's about understanding what actually works in our climate. Whether you're dealing with a warehouse in Long Island City or a retail plaza in Flushing, the material you choose will make or break your investment.

Look, I've seen every type of flat roof material fail and succeed. Some last five years, others push thirty. The difference? Picking the right system for your specific building and budget.

EPDM Rubber Roofing: The Workhorse

EPDM (ethylene propylene diene monomer) rubber is what I install on about 40% of my commercial jobs in Queens. This synthetic rubber membrane comes in black or white, and honestly, it's bulletproof when installed correctly.

The material cost runs around $3.50 to $7.00 per square foot, with installation bringing your total to $8-12 per square foot. For a typical 5,000 square foot warehouse roof, you're looking at $40,000 to $60,000 total.

Here's what I love about EPDM: it handles our temperature swings like a champ. From those brutal August days when the roof surface hits 160°F to January nights at 10°F, EPDM just flexes and keeps protecting. I've got EPDM roofs in Astoria that are pushing twenty-five years and still going strong.

The downside? Seams. EPDM comes in large sheets, but unless your roof is perfectly sized, you'll have seams that need to be welded or taped. That's where problems start if the installation isn't perfect.

TPO: The New Kid That Made Good

TPO (thermoplastic polyolefin) wasn't even on my radar fifteen years ago. Now it's probably 35% of my installs. This white membrane reflects heat like crazy, which is huge for energy costs in commercial buildings.

Material costs are similar to EPDM - $3.00 to $6.50 per square foot - but the white color can cut cooling costs by 20-30% in summer. Just last month we finished a 12,000 square foot medical building on Northern Boulevard, and the owner's already seeing the energy savings.

TPO seams are heat-welded, creating a watertight bond that's actually stronger than the membrane itself. But here's the catch - you need experienced installers. I've seen too many TPO failures from contractors who didn't understand proper welding techniques.

Modified Bitumen: Old School Reliability

Modified bitumen is asphalt with added polymers for flexibility. It's been around forever, and there's a reason - it works. We install it in two ways: torch-applied or self-adhering.

Cost-wise, you're looking at $4-8 per square foot installed. It's not the cheapest option, but the durability is incredible. I've got modified bitumen roofs in Elmhurst from the 1990s that are still solid.

The multi-layer system gives you redundancy. If the top layer gets damaged, you've still got protection underneath. Plus, repairs are straightforward - cut out the damaged section and patch it.

PVC Roofing: Premium Performance

PVC membrane is the Mercedes of flat roofing materials. It costs more upfront - $5-10 per square foot installed - but the chemical resistance and longevity are unmatched.

If your building deals with grease (restaurants), chemicals, or extreme weather exposure, PVC is worth every penny. The seams are heat-welded like TPO, but PVC is more flexible and handles thermal movement better.

I installed PVC on a Greek restaurant in Bayside five years ago. The grease and exhaust that would destroy other materials? PVC just shrugs it off.

Built-Up Roofing (BUR): The Traditional Choice

Built-up roofing is layers of asphalt and reinforcing fabric, topped with gravel or a cap sheet. It's been protecting buildings for over a century, and it's still relevant today.

The cost varies wildly based on the number of plies - typically $3-7 per square foot installed. A four-ply system will outlast a two-ply system, but you pay for that durability.

BUR handles foot traffic better than single-ply membranes. If you've got HVAC units, workers accessing equipment, or just general maintenance traffic, BUR takes the abuse.

Metal Roofing for Flat Applications

Standing seam metal roofing can work on low-slope commercial buildings, though it's not technically "flat." The panels run from ridge to gutter with minimal slope for drainage.

Steel costs $7-12 per square foot installed, aluminum runs $8-14 per square foot. The lifespan is exceptional - 30-50 years with proper maintenance.

Metal makes sense for certain applications. Large warehouses, manufacturing facilities, or buildings where fire resistance is crucial. Just remember - metal expands and contracts significantly, so proper fastening and thermal breaks are essential.

What Works Best in Queens?

Here's the thing about roofing materials for flat roofs in our area - you need to consider the salt air from the East River and Long Island Sound, the temperature extremes, and the reality of finding qualified contractors for repairs.

For most commercial buildings, I recommend EPDM or TPO. They're cost-effective, reliable, and every roofing contractor in Queens knows how to work with them. That matters when you need emergency repairs.

For buildings with specific challenges - chemical exposure, extreme foot traffic, or energy efficiency requirements - PVC or modified bitumen make sense despite the higher cost.

Installation Matters More Than Material

I can't stress this enough - the best flat roofing materials in the world won't help you if they're installed poorly. I've seen $200,000 TPO roofs fail in three years because the contractor cut corners on fastening patterns and seam welding.

Always check your contractor's license, insurance, and references. Ask to see recent jobs. A good installer will walk you through their process and explain why they recommend specific materials for your building.

Maintenance Considerations

Every flat roof material requires maintenance, but some are more forgiving than others. EPDM and modified bitumen are easier to repair - most roofing contractors can handle basic maintenance.

TPO and PVC require specialized equipment for welding repairs. Make sure you can find qualified service in your area. There's nothing worse than having a leak and discovering the only contractor who can fix your roof is booked for two weeks.

Built-up roofing needs the most maintenance - annual inspections, resealing penetrations, and eventual re-surfacing. But when properly maintained, BUR systems last decades.

Energy Efficiency and Cool Roofing

White or light-colored membranes can significantly reduce cooling costs. TPO and PVC in white are considered "cool roof" materials by Energy Star standards.

The energy savings are real. On a typical summer day in Queens, a black EPDM roof might reach 180°F while a white TPO roof stays at 120°F. That's a huge difference in heat transfer to your building.

Some utility companies offer rebates for cool roof installations. Con Edison has programs that can offset part of your roofing costs if you meet their efficiency standards.

Making Your Decision

The best flat roofing materials comparison starts with your specific needs. Budget is important, but don't make it the only factor. A roof that costs 20% more upfront but lasts twice as long is a better investment.

Consider your building's use, local weather conditions, and long-term plans. If you're selling in five years, basic EPDM might make sense. If this is a long-term hold, invest in premium materials.

At Flat Masters NY, we've installed every type of commercial flat roofing system across Queens. From small retail buildings to massive distribution centers, we match the material to the application. Because after two decades in this business, I know that the right roof isn't just about keeping water out - it's about protecting your investment for years to come.

Need help choosing the right flat roofing material for your commercial property? Call us at (917) 994-7618 for a detailed assessment and honest recommendations based on your specific needs and budget.