Professional Cold Flat Roof Construction Services Near You

After twenty-three years building flat roofs across Queens, I've installed more cold flat roof systems than I can count. Look, cold flat roof construction isn't just about slapping some membrane on top of your building and calling it a day - there's a science to it, especially here in New York where we get hammered by everything from nor'easters to those brutal summer heat waves.

Let me tell you what cold flat roof construction really means and why it might be exactly what your building needs.

What Is Cold Flat Roof Construction?

Here's the thing about cold flat roof construction - it's called "cold" because there's no insulation directly above the roof deck, creating a ventilated air space between your ceiling and the roof membrane. This air space stays at outdoor temperature, hence the name. The insulation sits below the roof deck, usually between or under the joists.

I was just explaining this to a building owner in Astoria last week. He kept asking why we call it "cold" when his building is heated. The roof structure itself runs cold because of that ventilated space - that's the key difference from warm roof systems where insulation goes above the deck.

Most of the cold flat roof construction projects we handle in Queens involve either apartment buildings built before 1980 or commercial properties where the owner wants maximum ventilation. The construction details matter more than people realize.

Cold Flat Roof Construction Details That Actually Matter

When I'm planning cold flat roof construction, three things keep me up at night: ventilation, vapor barriers, and drainage. Get any one wrong and you're looking at problems within five years.

Ventilation Requirements: You need continuous airflow from eave to eave, or eave to ridge if there's any slope. We install vents every 8-10 feet around the perimeter, and I always spec cross-ventilation. The building codes here in NYC require at least 1 square foot of vent area for every 150 square feet of ceiling area when you have a vapor barrier, or 1:300 without one.

The vapor barrier goes on the warm side - that's on or below your ceiling. Usually 6-mil polyethylene, though I prefer peel-and-stick membranes for better sealing around penetrations. Can't tell you how many moisture problems I've fixed because someone skipped this step or installed it wrong.

Structural Considerations: Your roof deck needs to handle not just the membrane and any equipment, but snow loads too. Here in Queens, we design for 30 psf ground snow load minimum. The deck itself - whether it's concrete, steel with metal decking, or wood - has to span properly between supports.

How To Build A Cold Flat Roof (The Real Process)

Building a cold flat roof starts way before you touch the membrane. First thing I do is verify the structural capacity with the building's engineer. You'd be amazed how many times someone calls us to "just replace the roof" and we discover the structure can't handle modern loading requirements.

The actual construction sequence goes like this:

- Install or verify proper structural support

- Install roof decking (steel, concrete, or wood depending on the building)

- Create the ventilated air space - usually 4-6 inches minimum

- Install perimeter and intermediate ventilation

- Apply the roofing membrane system

- Install proper drainage and any rooftop equipment

Here's what separates professional cold flat roof construction from the hack jobs I see too often: the membrane attachment. On concrete decks, we use mechanical fasteners through the membrane into concrete anchors. On steel decking, it's screws with large washers or plates. Wood decking gets screws or nails, depending on the membrane type.

The membrane itself - we mostly use EPDM, TPO, or modified bitumen in Queens. EPDM runs about $4.50-6.00 per square foot installed, TPO slightly more at $5.50-7.50, and modified bitumen sits in between. These prices include basic flashing but not major equipment work or structural repairs.

Flat Cold Roof Construction: Why Choose This System?

So why go with cold flat roof construction instead of a warm roof? Three main reasons in my experience:

Existing Building Constraints: If you've got an older building with limited ceiling height, cold roof construction lets you keep your interior space. The insulation stays below the deck where it probably already is.

Maintenance Access: With warm roof systems, if you need to get at the structure or fix a leak, you're cutting through insulation. Cold roofs give you that ventilated space to work in. Just last month we had to run new electrical conduit through a building on 31st Street - having that accessible space saved the owner thousands in demolition costs.

Moisture Management: When moisture does get into the system - and it will eventually - cold roofs can dry out through ventilation. Warm roofs trap moisture in the insulation, and that's when you get rot, mold, and structural problems.

But there are downsides too. Energy efficiency isn't as good as warm roof systems, and you need more attention to air sealing at the ceiling level. In Queens, with our heating costs, this matters.

Common Cold Flat Roof Construction Problems

I've been fixing other contractors' mistakes for decades, and the same issues keep coming up with cold flat roof construction.

Inadequate ventilation tops the list. Guys install a few soffit vents and think they're done. You need cross-flow ventilation, not just a couple of holes. I've seen buildings where condensation drips like rain inside the roof structure because there's no air movement.

Wrong vapor barrier placement comes in second. The vapor barrier goes on the warm side, period. I pulled apart a roof in Long Island City where someone installed it above the insulation - complete disaster. Moisture was condensing against the vapor barrier and rotting out the deck.

Drainage issues kill more flat roofs than anything else. Cold flat roof construction requires positive drainage to roof drains or scuppers, with backup overflow systems. The roof can't be dead flat - minimum 1/4 inch per foot slope to drains, though I prefer 1/2 inch per foot when possible.

Building A Cold Flat Roof: Material Selection

When I'm specifying materials for cold flat roof construction in Queens, I think about three things: weather resistance, longevity, and maintainability. The salt air from the East River and Long Island Sound eats up cheaper materials fast.

Membrane Options: EPDM rubber remains my go-to for most projects. It's been around forever, handles temperature swings well, and repairs easily. TPO offers better energy efficiency with its white surface, but quality varies by manufacturer. I stick with Carlisle, Firestone, or GAF for TPO.

Modified bitumen works great for cold roof applications, especially torch-applied systems. The multiple layers give you redundancy, and it's nearly bulletproof once installed correctly. Takes longer to install though, and costs more.

Insulation Considerations: Since the insulation goes below the deck in cold roof construction, you're usually working with batts or blown-in material between joists. Rigid foam works if you've got a suspended ceiling system. The key is maintaining the thermal barrier while allowing the roof structure to stay cold.

Cold Flat Roof Construction Cost Factors

Pricing cold flat roof construction depends on way more variables than most people realize. Square footage is just the starting point.

A basic cold flat roof replacement runs $6-12 per square foot in Queens, but that's for straightforward jobs with minimal complications. Add complex flashing details, equipment removal and replacement, or structural work, and you're looking at $15-25 per square foot easily.

New construction costs less per square foot because everything's accessible and there's no tearoff involved. We just finished a 15,000 square foot warehouse in Maspeth at about $8.50 per square foot for EPDM over steel decking.

But here's what drives costs up: existing conditions. If your current roof has multiple layers, that's extra tearoff and disposal. Rotten decking means structural repair. Poor drainage requires slope correction with tapered insulation or lightweight concrete.

Equipment work kills budgets. Moving HVAC units, reconnecting gas lines, upgrading electrical - that's all extra. Budget at least $2,000-5,000 per piece of major equipment that needs to be worked around.

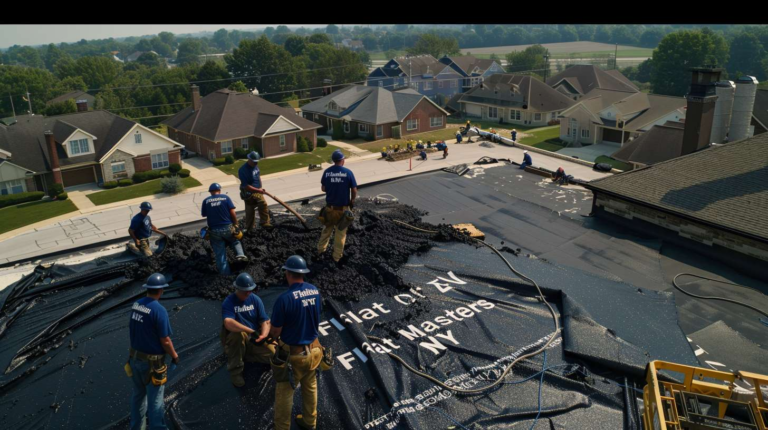

Why Flat Masters NY For Your Cold Flat Roof Construction

Look, I'm not going to tell you we're the cheapest option in Queens. We're not. But after handling over 2,000 flat roofs across the borough, I know what works and what doesn't.

My team understands cold flat roof construction details that matter. We size ventilation properly, install vapor barriers correctly, and build drainage systems that actually work. Carlos, my foreman, has been with me for twelve years - he knows these systems inside and out.

We use quality materials from suppliers I trust. Most of our EPDM comes from Beacon Supply on Northern Boulevard - they've been supporting contractors here for decades. When problems come up, and they always do, we've got relationships that get things solved fast.

Every cold flat roof construction project gets a 10-year warranty on our workmanship, backed by manufacturer material warranties. We're licensed (License 704521), insured, and bonded. More importantly, we're local - when you need service, we're twenty minutes away, not calling you back from New Jersey next week.

The building codes here in New York City are stricter than most places, and they change regularly. We stay current with DOB requirements and handle all permitting. Most importantly, we build these roofs to last more than the warranty period.

Getting Started With Your Cold Flat Roof Project

If you're thinking about cold flat roof construction for your Queens property, the first step is a proper assessment of what you've got now. I can usually tell within fifteen minutes whether cold roof construction makes sense for your building.

We provide detailed estimates that break down materials, labor, and any structural work needed. No surprises, no change orders unless you request additional work. The estimate includes timeline, cleanup, and what permits we'll need.

For emergency repairs, we respond 24/7. But for planned cold flat roof construction, spring and fall are your best windows. Summer heat makes membrane work harder, and winter... well, you don't want to be tearing off roofs when it's 20 degrees outside.

Call Flat Masters NY at (917) 994-7618 for a free assessment of your flat roof project. We've been building cold flat roof systems in Queens since 2001, and we'll be here for the next twenty years making sure your roof performs exactly as it should.