Free Flat Roof Material Calculator: Get Accurate Estimates Fast

Look, after 22 years installing flat roofs across Queens, I can tell you that having the right material calculations upfront saves you hundreds - sometimes thousands - of dollars and prevents those nightmare mid-project runs to the supply house. A proper flat roof material calculator isn't just about square footage; it's about understanding waste factors, overlap requirements, and the specific demands of New York's brutal weather cycles.

Here's what I've learned from over 1,800 flat roof installations from Astoria to Jamaica: most homeowners underestimate materials by 15-20%, then get hit with rush delivery charges when they run short. That's why we developed our systematic approach to flat roofing calculations.

Roofing Cost Calculator

Get Your Free Estimate in 5 Simple Steps

Your Estimated Price Range:

Final pricing may vary based on actual conditions.

Get your personalized quote with exact pricing.

Essential Measurements for Your Flat Roof Material Calculator

The foundation of any accurate flat roofing calculator starts with precise measurements, but there's more to it than just length times width. On a job last month on 48th Street in Sunnyside, the homeowner thought they needed materials for 800 square feet. After accounting for the parapet walls, HVAC penetrations, and proper drainage slopes, we actually needed materials for 950 square feet.

You'll need these measurements:

- Total roof area (length × width for each section)

- Parapet wall height and perimeter

- Number and size of roof penetrations

- Drainage areas and slope requirements

- Edge details and perimeter footage

But here's something most online calculators miss - the actual usable area versus total area. In Queens, with our narrow lots and adjoining buildings, you're dealing with complex shapes, not simple rectangles.

Material Types and Calculation Differences

Each flat roofing system requires different calculation methods, and I can't stress this enough - the material type completely changes your waste factors and installation requirements.

EPDM Rubber Roofing: This is where most DIY calculations go wrong. EPDM comes in specific roll widths - typically 10', 15', 20', and 25'. You can't just divide your total square footage by the roll size. On a 24' wide roof, you'll need a 25' roll, creating 12 square feet of waste per linear foot. That adds up fast.

For a typical 1,200 square foot Queens rowhome, you're looking at roughly 15-18% waste factor with EPDM, not the 10% most online calculators suggest. The salt air from the East River and our freeze-thaw cycles mean you also need extra material for proper seam overlaps.

Modified Bitumen: Here's where experience really matters. Modified bitumen requires a 6" overlap on all seams, and in our climate, I always recommend an additional 2" beyond code requirements. Your base calculations need to account for this overlap, plus the cap sheet if you're doing a two-ply system.

TPO Single Ply: The welded seams on TPO require precision in your material calculations. Unlike EPDM's glued overlaps, TPO seams need exact positioning. Waste factors run about 12-14% for most residential projects in our area.

Critical Factors Most Calculators Miss

I've seen too many homeowners get burned by generic online calculators that don't account for real-world conditions. Last week, a customer in Elmhurst called me frantically because their "calculated" materials left them 200 square feet short with a rainstorm approaching.

Here's what actually matters in Queens:

Weather-specific requirements: Our temperature swings from sub-zero winters to 90+ summers mean material expansion and contraction considerations. You need additional material at edges and penetrations to handle this movement.

Building code compliance: NYC building codes require specific fire ratings and installation methods that affect material quantities. The Department of Buildings isn't flexible on these requirements.

Substrate conditions: Most older Queens buildings have multiple layers of existing roofing. Sometimes we're installing over concrete, sometimes over wood decking, sometimes over existing modified bitumen. Each situation changes your material calculations and accessory requirements.

Step-by-Step Calculation Process

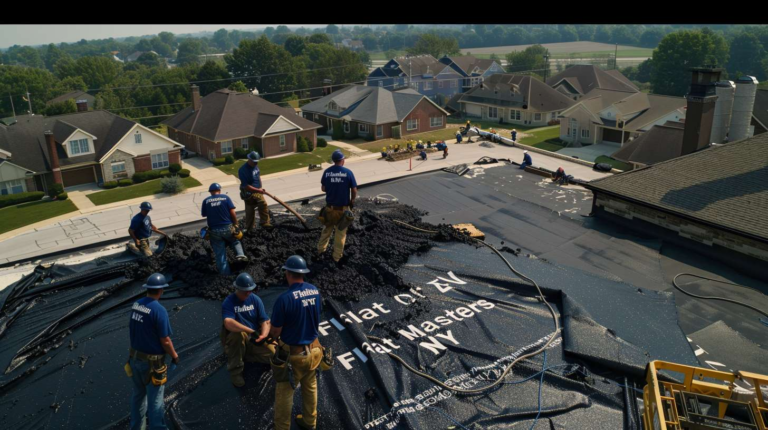

Here's how we calculate materials at Flat Masters NY - this is the process we've refined over thousands of installations.

Step 1: Base Area Calculation

Measure each roof section separately. Don't try to estimate complex shapes as simple rectangles. For L-shaped or multi-level roofs, break them into individual rectangles and calculate each one.

Step 2: Add Waste Factors

This varies by material and roof complexity:

- Simple rectangular roofs: 10-12% waste

- Complex shapes with multiple penetrations: 15-18% waste

- Roofs requiring multiple seams: 18-22% waste

Step 3: Calculate Edge Materials

Measure your perimeter footage and add materials for:

- Drip edge and fascia work

- Parapet cap and counterflashing

- Expansion joints

- Walkway pads around HVAC units

Step 4: Penetration Materials

Each roof penetration needs specific materials. Count your:

- Plumbing vents

- HVAC equipment

- Electrical conduits

- Chimneys

Each one requires flashing, sealants, and often custom fabricated pieces.

Flat Roof Insulation Calculations

Most homeowners forget about insulation in their material calculations, but in New York's climate, proper insulation isn't optional - it's required by code and essential for energy efficiency.

Insulation calculations are straightforward: total roof area minus penetration areas. But here's where it gets tricky - insulation board sizes and your roof dimensions rarely match perfectly. Polyiso boards come in 4'×8' sheets, so you need to calculate how many full sheets you'll need, plus partial sheets for odd dimensions.

For a 24'×30' roof (720 sq ft), you'd need 23 full sheets of 4'×8' insulation (736 sq ft of coverage), giving you minimal waste. But for a 25'×31' roof (775 sq ft), you'd need 25 sheets (800 sq ft), creating more waste but ensuring complete coverage.

Drainage and Slope Materials

Here's something that drives me crazy about generic flat roofing calculators - they completely ignore drainage requirements. In Queens, with our heavy rainstorms and winter freeze cycles, proper drainage isn't just recommended, it's critical for preventing catastrophic failures.

You need to calculate materials for:

- Tapered insulation systems for positive drainage

- Drain assemblies and sumps

- Scupper boxes and overflow drains

- Cricket installations around HVAC equipment

A properly sloped roof might require 20-30% more insulation materials than a flat calculation suggests, depending on your drainage design.

Local Supply Considerations in Queens

Something most online calculators can't account for is local material availability and delivery logistics. We work with suppliers like Beacon Building Products on Northern Boulevard and SRS Distribution in Long Island City. Understanding their stock rotations and delivery schedules affects how you calculate and order materials.

Some materials are only available in specific quantities. EPDM adhesive, for example, comes in 5-gallon buckets. For a 1,000 square foot roof, you might need 2.5 gallons, but you'll have to buy 3 buckets. Factor these minimums into your calculations.

Cost Factors in Material Calculations

A flat roof material calculator isn't just about quantities - it's about understanding how material choices affect your total project cost. In our market, here's what I'm seeing for material costs:

EPDM rubber roofing runs $3.50-$5.50 per square foot for materials, but the accessories and adhesives add another $1.50-$2.00 per square foot. Modified bitumen materials cost $2.50-$4.00 per square foot, but require additional equipment rentals for installation.

TPO materials cost $2.00-$3.50 per square foot, but the welding equipment and expertise required often make labor costs higher.

Common Calculation Mistakes to Avoid

After two decades in this business, I've seen every possible calculation error. Here are the ones that cost homeowners the most money:

Underestimating edge work: Edge details and perimeter work often require 25-40% of your total material cost, but most people budget maybe 10%. On a recent project in Forest Hills, the customer calculated $2,800 for membrane materials but forgot about the $1,200 in edge and flashing materials.

Ignoring fastener requirements: Fasteners aren't cheap, and the quantities add up quickly. A mechanically-attached EPDM system might need 8-12 fasteners per square foot, plus plates and washers. That's potentially 10,000+ pieces for a modest residential roof.

Forgetting primer and sealants: These "minor" items can easily add $300-$600 to a project. EPDM primer costs about $45 per gallon, and you'll typically need one gallon per 150-200 square feet of membrane.

Seasonal Considerations for Material Calculations

In Queens, when you install matters for material calculations. Winter installations require different products and quantities than summer work.

Cold-weather adhesives and sealants cost more and have different coverage rates. Winter installations also require additional materials for temporary weather protection during the installation process.

Summer installations deal with thermal expansion issues. Materials expand significantly in our July heat, so you need different overlap calculations and expansion joint materials.

Professional vs. DIY Material Calculations

Look, I get it - everyone wants to save money and many homeowners are handy. But here's the reality: a professional flat roofing contractor has access to better pricing, bulk discounts, and exact material specifications that can save you 15-25% on material costs alone.

We buy EPDM membrane at $2.20 per square foot; homeowners pay $3.50-$4.00 at retail. Over a 1,000 square foot roof, that's $1,300-$1,800 in material cost difference, not including the specialized tools and equipment needed for proper installation.

Plus, when we calculate materials, we account for warranty requirements, code compliance, and long-term performance. A small error in material calculations or installation can void your warranty and create expensive problems down the road.

Getting Started with Your Flat Roof Material Calculator

If you're determined to calculate materials yourself, start with accurate measurements and add appropriate waste factors for your specific situation. Remember that flat roofing isn't just about the membrane - you need to calculate insulation, fasteners, adhesives, flashings, and drainage materials as a complete system.

But honestly? After seeing hundreds of DIY calculation errors over the years, I recommend getting professional estimates from at least two qualified contractors. At Flat Masters NY, we provide detailed material breakdowns with our estimates, so you know exactly what goes into your project.

For complex roofs or if you're dealing with insurance claims, professional calculations aren't just helpful - they're essential for ensuring your project meets code requirements and warranty standards.

Need help with your flat roof material calculations? Give us a call at (917) 994-7618. We'll walk through your project and provide accurate material estimates based on 22 years of experience with Queens flat roofing projects.